This model is widely used for large parts and molds with a tonnage greater than 350 tons, other advantage is the size of the mold base to be more compact and small, so the cost for the mold base can also be reduced, and if the size is smaller base can mold into tonnase also smaller

Wednesday, December 22, 2010

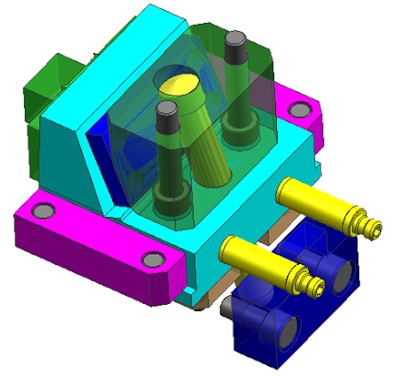

using mold base become locking block of slider unit

moldbase sometimes can be used for the locking block on the slider unit, this is basedon several reasons, for example, to reduce cost, by reducing the insert locking block, the other reason is required surface area for the locking block.

illustration picture above shows the angular pins are bolted to the mold base and the mold base made pocket instead of locking block,

to keep the process easy to do maintenance, should be installed oil slide plate, so when it can wear easily replaced without the need to change their plate slider block.

This model is widely used for large parts and molds with a tonnage greater than 350 tons, other advantage is the size of the mold base to be more compact and small, so the cost for the mold base can also be reduced, and if the size is smaller base can mold into tonnase also smaller

This model is widely used for large parts and molds with a tonnage greater than 350 tons, other advantage is the size of the mold base to be more compact and small, so the cost for the mold base can also be reduced, and if the size is smaller base can mold into tonnase also smaller

Sunday, November 21, 2010

Loose core for ejecting undercut at injection mold

Picture above shows the loose core, or often also called slope ejectors or inclined pin, loose cores is one method to overcome the undercut on the product, particularly undercut the core position facing into the bottom (towards the sprue bush-center of mold) that undercut it can not be made simply by using slider method, part of the loose core complete with mold base include:

1. Top clamping Plate

2. stripper plate

3. cavity plate

4. core plate

6. support plate

7. top ejector plate

8. bottom ejector plate

9. bottom clamping plate

10. loose core rod

11. loose slide unit

12. bushing

for more details look at the picture below, which shows the current position of loose cores prior to the occurrence of loose core ejecting position after ejecting process, shortly after the mold is closed and the injection process, loose cores in the closed position (note the closed mold), after the injection process is complete done, at the push of ejector rod, ejector plate both upper and lower parts helped push out through the ejector, while the loose-core because it has a certain slope (generally 8-15) when driven will move slowly into center with the aid of friction on inclined leader pin bushings, so the position Loose cores are separated from the undercut product (mold opened)

Slide the unit mounted on the ejector plate is always on the top or at the bottom, and the main mover of the loose core are ejector rod simultaneously with the process of ejecting, points to consider in designing the loose core is strokes and angles used, too little angle of it can reduce the occurrence of abrasion (wear) but required a long stroke.

If angle is too large can cause the inclined pin (loose core) broken because of the occurrence of high abrasion, but required a shorter stroke. The angle that is used is usually between 8-15 0, while the stroke must be exceeded 5 mm or more to keep the loose core is certain regardless of the undercut in the product.Friday, November 12, 2010

Loose cavity inner undercut release method in injection Molding

one way to release the undercut is to loose cavity, the opposite of loose cores, loose inner cavity is used to remove the undercut in the cavity area, note the image below for more details,

1 = top plate

2 = runner stripper plate

3 = cavity plate

4 = core plate

5 = locking block for loose cavity

6 = angular pin for loose cavity system

7 = loose insert cavity

some designers also say that with the inner mold cavity slider, whatever his name is, in essence, functions and works the same way. when the first opening between the top runner stripper plate (2) with the cavity plate (3) top plate will pull locking block (5) together with the angular pin (6), aided by the spring on the insert cavity, this movement causes the loose insert cavity to move straight straight to the angular movement of the pin, as a result of friction between the angular pin with a hole in the loose insert cavity.

when construction is used, ie if your product has undercut formation on a position in the cavity region, angular corners and locking block commonly used ranged from 8 to 20 degrees, above the angle can cause angular cartilage pin was broken, because the force that fought too large.

Another thing to note is the stroke, you must ensure that the stroke of movement of loose cores must be secure, which is about the length undercut products coupled with the 5-10 mm.

1 = top plate

2 = runner stripper plate

3 = cavity plate

4 = core plate

5 = locking block for loose cavity

6 = angular pin for loose cavity system

7 = loose insert cavity

some designers also say that with the inner mold cavity slider, whatever his name is, in essence, functions and works the same way. when the first opening between the top runner stripper plate (2) with the cavity plate (3) top plate will pull locking block (5) together with the angular pin (6), aided by the spring on the insert cavity, this movement causes the loose insert cavity to move straight straight to the angular movement of the pin, as a result of friction between the angular pin with a hole in the loose insert cavity.

when construction is used, ie if your product has undercut formation on a position in the cavity region, angular corners and locking block commonly used ranged from 8 to 20 degrees, above the angle can cause angular cartilage pin was broken, because the force that fought too large.

Another thing to note is the stroke, you must ensure that the stroke of movement of loose cores must be secure, which is about the length undercut products coupled with the 5-10 mm.

Saturday, October 2, 2010

Top 6 Injection Molding Company

it's difficult to list all company that provide any solution about injection machine, include manufacturer, injection molder, machine maker, and injection design, based on the survey is limited to friends and colleagues associated with the injection mold, which many ads appear on Google, and companies that contribute most in the book and seeing appear in the books of injection mold, here I will be showing 6 of the most famous course according to my own version, because I do not have complete data. assessment should be based on the type of machine made, proceeds, income per year, the number of employees, average employee welfare, customer satisfaction and how many problems that arise from the resulting product.

1. HUSKY,

if you often read a book mold, of course, will easily recognize these companies from Canada,

Husky designs and manufactures the industry’s most comprehensive range of complete, integrated injection molding systems for a variety of key markets. Our systems include Hylectric, HyPET, HyPAC and HyCAP

* Hylectric – our base platform on which we've build a wide range of specialized systems for a variety of applications including closures, thinwall/IML, pails, and cutlery

* HyPET – lightweight PET preforms

* HyCAP – high output beverage closure manufacturing

* HyPAC – high performance thinwall packaging

2.SUMITOMO DEMAG

Sumitomo (SHI) Demag is one of the leading manufacturers of plastic injection moulding machines anywhere in the world together with its Japanese parent group. More than 3,000 workers come up with and produce outstanding machines and solutions at 4 production locations in Germany, Japan and China.

develop and manufacture a range of all-electric,hybrid and hydraulic injection moulding machines with clamping forces ranging from 180 kN to 40,000 kN.

3. ARBURG

is one of the leading global manufacturers of injection moulding machines. Robotic systems, complex production cells and other peripherals are also included in our product range.

4. NISSEI

This company is very famous in world injection machine, because kepresisianya especially for products with small tonnage, nissei producing machine with a capacity of 7 tons to 1500 tons, penjualanya many areas of Asia and America

5. DONGSHIN

Dongshin Hydraulics has continually striven to be one of the

premier manufacturers of injection molding machines world-wide through our continual investment in reserch and development-with 38 years of acquired technology and the closest co-operation with our customers.

since its establishment in 1960 the company was growing rapidly and could become the best performing companies in Korea in 2007, the marketing is a broad range ranging from southeast asia, korea, china to India and Africa.

6. JSW

As a leader in the industry, JSW provides a full line of injection molding machines, ranging from small to ultra-large models, which offer ease of operation, safety, and environment-friendly improvements such as energy- and space-saving features. Moreover, we offer technical support in line with customer needs, including consulting service and systems for factory automation. JSW has established a global network which covers the United States, Europe, and Asia

1. HUSKY,

if you often read a book mold, of course, will easily recognize these companies from Canada,

Husky designs and manufactures the industry’s most comprehensive range of complete, integrated injection molding systems for a variety of key markets. Our systems include Hylectric, HyPET, HyPAC and HyCAP

* Hylectric – our base platform on which we've build a wide range of specialized systems for a variety of applications including closures, thinwall/IML, pails, and cutlery

* HyPET – lightweight PET preforms

* HyCAP – high output beverage closure manufacturing

* HyPAC – high performance thinwall packaging

2.SUMITOMO DEMAG

Sumitomo (SHI) Demag is one of the leading manufacturers of plastic injection moulding machines anywhere in the world together with its Japanese parent group. More than 3,000 workers come up with and produce outstanding machines and solutions at 4 production locations in Germany, Japan and China.

develop and manufacture a range of all-electric,hybrid and hydraulic injection moulding machines with clamping forces ranging from 180 kN to 40,000 kN.

3. ARBURG

is one of the leading global manufacturers of injection moulding machines. Robotic systems, complex production cells and other peripherals are also included in our product range.

4. NISSEI

This company is very famous in world injection machine, because kepresisianya especially for products with small tonnage, nissei producing machine with a capacity of 7 tons to 1500 tons, penjualanya many areas of Asia and America

5. DONGSHIN

Dongshin Hydraulics has continually striven to be one of the

premier manufacturers of injection molding machines world-wide through our continual investment in reserch and development-with 38 years of acquired technology and the closest co-operation with our customers.

since its establishment in 1960 the company was growing rapidly and could become the best performing companies in Korea in 2007, the marketing is a broad range ranging from southeast asia, korea, china to India and Africa.

6. JSW

As a leader in the industry, JSW provides a full line of injection molding machines, ranging from small to ultra-large models, which offer ease of operation, safety, and environment-friendly improvements such as energy- and space-saving features. Moreover, we offer technical support in line with customer needs, including consulting service and systems for factory automation. JSW has established a global network which covers the United States, Europe, and Asia

Tuesday, August 17, 2010

wall thickness and sink mark estimation

Uniform wall thickness in plastic part design is critical.Non-uniform wall thickness can cause serious warpage and dimensional control problems.One of the easiest ways to cure this problem is change the part geometry by adding ribs. The use of ribs is a practical way and economical means of increasing the structural strength of a part. it is more economical to use ribs than increase wall thickness, But there are guidelines that govern adding ribs without causing sink marks or surface blemishes to your parts. in parts requiring good surface appearance, ribs should be avoided as sink marks on the opposite surface will surely appear.

The wall thicknesses of an injection-molded part generally range from 2 mm to 4 mm (0.080 inch to 0.160 inch). Thin wall injection molding can produce walls as thin as 0.5 mm (0.020 inch).

Rib thickness should be less than wall thickness. A rib thickness of 60% to 80% of nominal wall thickness is recommended. (plastics1.com)

using finite element software or relevant software for injection mold like, Mold flow, C-Mold, Etc, we can estimate the sink mark that will appear, picture below for example, with different rib we can see that sink mark result also different, first rib (from left) have 0.6 * thickness part, second rib thickness same with part thickness,

Thick sections cool slower than thin sections. The thin section first solidifies, and the thick section is still not fully solidified. As the thick section cools, it shrinks and the material for the shrinkage comes only from the unsolidified areas, which are connected, to the already solidified thin section (efunda.com)

non uniform wall thickness also can cause voids and non-uniform shrinkage, for example in a sharp outside corner and a properly filleted inside corner could present problems due to the increased wall thickness at the corner. to prevent that we can add additional radius or shape like picture below

How About Bosses?

Bosses are used for locating, mounting, and assembly purposes. There are boss design guidelines that must be followed to insure the highest quality in molded parts. Again, one of the main points to consider is nominal wall thickness. Too many times bosses are designed with thick wall sections that can affect the appearance of the plastic part and the final product. (plastic1.com)

As a rule, the outside diameter of a boss should be 2 to 3 times the hole diameter to ensure adequate strength. The same principles used in designing ribs pertain to designing bosses, that is, heavy sections should be avoided to prevent the formation of voids or sink marks and cycle time penalty.Less good design of bosses can lead to sink marks.

to prevent that, design the boss like picture below is preferred

.Boss diameter, wall thickness, and height design parameters. While boss heights vary by design, the following guidelines will help avoid surface imperfections like sink marks and voids: the height of the boss should be no more than 2 1/2 times the diameter of the hole in the boss.

Monday, August 2, 2010

Locking Block With Angular Slider

3:53 PM

Mold Construction, mold design, slider parts

What should you do when the slider design and found that the angular slider too long? There are many ways to change the design so that the angular length of the slider pins are still reasonable when compared to its diameter.in design between the angular diameter and length of the slider pins should be noted, the length of angular slider pins that are too long can lead to easily broken when the mass production run, especially if the small angular diameter, the way the installation is also a concern to be easy in the process of repair when damage occurs.

the above picture, I took when designing the angular pin slider, when the client wants the angular pin slider must exist, and based on the calculation of stroke, it turns out the angular pin length is too long, surely this is dangerous and i should change the design concept.

other than dangerous, the above design concept is also difficult in maintenance because if the angular pin broke the mold base must be dropped from the injection machine, disassembly the mold then can be replaced, this is because the angular pin must be in pairs from the top plate embedded in the cavity

Locking Block With Angular Slider

This design concept in addition to saving space, saving the long angular slider also has the advantage of easy installation and maintenance, although the angular pin mold was broken when used for production, the mold does not need to send down from the injection machine to replace it. look at picture below

on the design concept above, I only use one bolt to tighten to the cavity plate, simple but I'm sure I could save the angular length of approximately half of the angular slider before. The above concept also facilitates the repair process.

The second alternative was similar, but the difference is the number of bolts are used and how big a part of the locking block affixed to the cavity plate, the first altenative collar only are plugged into the cavity plate, and the bolts, of course, only part that holds the slider in the section just the collar. A second alternative is different from all bagianya embedded in the plate cavity.

I chose the second alternative concept, the concept was made 3D and 2D drafting calculations based on a stroke, for details, under the following 3D image is the result of the 3D design of the second alternative.

Saturday, June 26, 2010

slider construction : cam or angular pin

11:34 AM

Mold Construction, slider parts

posts related to construction and part-bagianya slider has been my post, about the cooling on the slider, the basic construction for the slider, the slider and the main part, please see previous post to learn the basic construction and when we should use the slider, This post will discuss about when we need to use of the slider that use angular pin or just cam slider, what advantages and disadvantages of both types of construction such slider.

ANGULAR PIN

basically, the type of construction of the slider based on how to pull out the core slider is divided into three types, first use the angular pin,using the force of the angular pin at a certain angle, the slider block would be pull out, the second is a cam slider, just use the thrust of the spring and stopper on the slider, and calculating a stroke, cam slider allows you to easily pull the slider core, the third is the use of hydraulic or pneumatic system to pull the slider core, specifically for the third way is needed so that movements of individual controls in accordance when the slider open mold and mold close.picture below shows slider with angular pin system.

picture above shown standard complete construction for slider, it's include cooling plug, stopper (blue color), adjustment plate between locking block and slider core(blue), guide rel (pink) etc. angular pin system very common use in slider system, Angular sometimes do not have a round pin, shape the box is also commonly used, actually used the same angle, both will be used by considering the strength, structure, mold, and the available space.

The advantage is the use of angular pins can be used for parts that have undercut short or long, easy to maintain when the angular broken, just enough to change the angular pin. inexpensive in manufacture, and can be used for long-stroke slider to medium, the angular pin length has not touched bottom plate.

for instance,look at picture above if undercut wide for most of the parts, use the slider two pins with a diameter sufficient, then you will get a strong slider construction and safe.

CAM SLIDER

while the slider does not require angular cam pin, the cam slider there are several types of commonly used, the clamp type, two angle type, cam units type and one direction cam. because in using the cam to take calculation of a stroke is used, why?? it's to prevent slider core not be separated from the locking block, and the strength of the spring, so that true core slider can move and hit the stopper. cam slider can only be used for minor stroke (0.5 mm-5mm), small undercut, and not too wide undercut form.

a benefit is a cam slider can be used for high cycle time, mold construction, saving space, and easy assembly.

whereas the less than the limited form that can be undercut in the form, was difficult in the manufacture and maintenance.

ANGULAR PIN

basically, the type of construction of the slider based on how to pull out the core slider is divided into three types, first use the angular pin,using the force of the angular pin at a certain angle, the slider block would be pull out, the second is a cam slider, just use the thrust of the spring and stopper on the slider, and calculating a stroke, cam slider allows you to easily pull the slider core, the third is the use of hydraulic or pneumatic system to pull the slider core, specifically for the third way is needed so that movements of individual controls in accordance when the slider open mold and mold close.picture below shows slider with angular pin system.

picture above shown standard complete construction for slider, it's include cooling plug, stopper (blue color), adjustment plate between locking block and slider core(blue), guide rel (pink) etc. angular pin system very common use in slider system, Angular sometimes do not have a round pin, shape the box is also commonly used, actually used the same angle, both will be used by considering the strength, structure, mold, and the available space.

The advantage is the use of angular pins can be used for parts that have undercut short or long, easy to maintain when the angular broken, just enough to change the angular pin. inexpensive in manufacture, and can be used for long-stroke slider to medium, the angular pin length has not touched bottom plate.

for instance,look at picture above if undercut wide for most of the parts, use the slider two pins with a diameter sufficient, then you will get a strong slider construction and safe.

CAM SLIDER

while the slider does not require angular cam pin, the cam slider there are several types of commonly used, the clamp type, two angle type, cam units type and one direction cam. because in using the cam to take calculation of a stroke is used, why?? it's to prevent slider core not be separated from the locking block, and the strength of the spring, so that true core slider can move and hit the stopper. cam slider can only be used for minor stroke (0.5 mm-5mm), small undercut, and not too wide undercut form.

a benefit is a cam slider can be used for high cycle time, mold construction, saving space, and easy assembly.

whereas the less than the limited form that can be undercut in the form, was difficult in the manufacture and maintenance.

Sunday, May 9, 2010

Troubleshooting warpage on injection molds

Warping, Part Distortion is shows up as parts being bowed, warped, bent or twisted beyond the normal specification outlined on the drawing.Warpage occurs when there are variations of internal stresses in the material caused by a variation in shrinkage. Warped parts may not be functional or visually acceptable.

Temperature differences from one side of the mold to the other can lead to layers freezing and shrinking at different times and generating internal stresses. Temperature differences from one side of the mold to the other (differential cooling).

2. Inconsistent shrinkage or non uniform stress due excessive orientation of shringkage.Variations in the magnitude of shrinkage in directions parallel and perpendicular to the material orientation direction (orientation effects).

Process conditions variations such as inconsistent packing and varying mold and melt temperatures; low pressure, mold temperature of ejection too hot, Material variations such as property variations, varying moisture content, inconsistent melt and pigmentation;

Main Causes

1.Non-uniform coolingTemperature differences from one side of the mold to the other can lead to layers freezing and shrinking at different times and generating internal stresses. Temperature differences from one side of the mold to the other (differential cooling).

2. Inconsistent shrinkage or non uniform stress due excessive orientation of shringkage.Variations in the magnitude of shrinkage in directions parallel and perpendicular to the material orientation direction (orientation effects).

Process conditions variations such as inconsistent packing and varying mold and melt temperatures; low pressure, mold temperature of ejection too hot, Material variations such as property variations, varying moisture content, inconsistent melt and pigmentation;

Possible Solutions

- Adjust melt Temperature (increase to relieve molded-in stress, decrease to avoid overpacking). stress, decrease to avoid over packing). stress, decrease to avoid over packing).

- Check gates for proper location and adequate size.

- Check mold knockout mechanism for proper design and operation.

- Equalize/balance mold temperature of both halves.

- Increase injection-hold.

- Increase mold cooling time.

- Perhaps one of the easiest things to alter is the temperature of the coolant. It may be useful to run two additional Cool analyses with the coolant inlet temperatures at say plus and minus 5°C with respect to the original inlet temperature used

- Relocate gates on or as near as possible to thick sections.

- Try increasing or decreasing injection pressure.

- Use thinner wall sections with ribs. Thicken only those wall sections that require extra material for structural stability and that cannot be strengthened using another method.

- Change the part geometry. Add features such as stiffening ribs to the design. Change the part design to avoid thick sections and reduce the thickness of any features that intersect with the main surface.

Wednesday, March 24, 2010

Troubleshooting weld lines and meld lines on injection molds

In manufacturing, the Weld line or Knit line or Meld line is the line where two flow fronts meet when there is the inability of two or more flow fronts to "knit" together, or "weld", during the molding process. These lines occurs usually around holes or obstructions and cause locally weak areas in the molded part.

A weld or meld line is a weakness or visible flaw created when two or more flow paths meet during the filling process. Weld lines can be caused by material flowing around holes or inserts in the part, multiple injection gates or variable wall thickness where hesitation or "race tracking" can occur. If the different flow fronts have cooled before meeting, they don't interfuse well and can cause a weakness in the molded part. A line, notch and/or color change can appear.

What Caused Weld or Melt Line?

A meld line occurs when two moving melt fronts converge and flow parallel to each other. Weld and meld lines are generally caused by holes or inserts in the part, multiple gates, variable wall thickness or hesitation and race track effects.

explanation from http://www.imtechdesign.com/ give brief reason why and when weld line, and melt line will occurs.

a meeting angle, smaller than 135º produces a weld line; greater than 135º, a meld line. Note that the weld line surface mark disappears when the meeting angle reaches 120º to 150º. Normally, weld lines are considered to be of lower quality than meld lines, since relatively less molecular diffusion occurs across a weld line after it is formed. However, there is always an exception to the rule and some materials by nature tend to exhibit more visible weld lines irrespective of the angle. In addition many fillers and additives also highlight weld & meld lines. Glass fibres and metallic pigments are good examples.

Weld lines, melt lines or Knit lines could be caused by different causes:

- Low temperature of molding machine barrel

- Inadequate back pressure

- Injection pressure or injection speed is too low

- Low mold temperature

- Small injection gates and/or runners

- Improper location of injection gate

- Excessive gate land length

- Improper flow rate of injected materials

- Inconsistent process cycle

Weld Line and Physical Properties

A study of the effect that weld lines and orientation have on physical properties of molded parts was undertaken to establish general guidelines for use in part design. an experiment by dupont show that between polymer orientation, Weld Lines. And tensile Strength have Relationship, see graph below.

These results show the importance of gate location and the need for the product

designer to coordinate his efforts with the tool builder. The gate should be located

both to avoid weld lines in high stress areas and to take full advantage of glass fiber reinforcement. Techniques the designer might use to reduce stress level at a weld line include increasing the wall thickness or adding ribs.

Solution

- This can be done by changing the polymer injection location or altering wall thicknesses to set up a different fill time.

- increasing mold temperature, melt temperature, injection rate and pressure.

- Increased mold venting or addition of flow tabs also can help turn a bad weld into

a good weld

- Change the gate positions.

- Change the part thickness.

- Optimize runner system design. Reduce runner dimensions and maintain the same flow rate to use shear heating to increase the melt temperature at the flow front

- Instead, it often helps to increase the injection velocity, decrease the fill time, and increase the shear rate, which can lower the viscosity of the polymer during fill and thereby allow for better chain entanglement and better packing. Increasing pack or hold pressure also helps, as well as having longer pack and hold times. Increasing pack or hold pressure helps to eliminate low-pressure conditions at the weld line. Another tactic to promote more chain entangling at the weld line is to raise the mold temperature 10° C (20° F).

A weld or meld line is a weakness or visible flaw created when two or more flow paths meet during the filling process. Weld lines can be caused by material flowing around holes or inserts in the part, multiple injection gates or variable wall thickness where hesitation or "race tracking" can occur. If the different flow fronts have cooled before meeting, they don't interfuse well and can cause a weakness in the molded part. A line, notch and/or color change can appear.

What Caused Weld or Melt Line?

A meld line occurs when two moving melt fronts converge and flow parallel to each other. Weld and meld lines are generally caused by holes or inserts in the part, multiple gates, variable wall thickness or hesitation and race track effects.

explanation from http://www.imtechdesign.com/ give brief reason why and when weld line, and melt line will occurs.

a meeting angle, smaller than 135º produces a weld line; greater than 135º, a meld line. Note that the weld line surface mark disappears when the meeting angle reaches 120º to 150º. Normally, weld lines are considered to be of lower quality than meld lines, since relatively less molecular diffusion occurs across a weld line after it is formed. However, there is always an exception to the rule and some materials by nature tend to exhibit more visible weld lines irrespective of the angle. In addition many fillers and additives also highlight weld & meld lines. Glass fibres and metallic pigments are good examples.

Weld lines, melt lines or Knit lines could be caused by different causes:

- Low temperature of molding machine barrel

- Inadequate back pressure

- Injection pressure or injection speed is too low

- Low mold temperature

- Small injection gates and/or runners

- Improper location of injection gate

- Excessive gate land length

- Improper flow rate of injected materials

- Inconsistent process cycle

Weld Line and Physical Properties

A study of the effect that weld lines and orientation have on physical properties of molded parts was undertaken to establish general guidelines for use in part design. an experiment by dupont show that between polymer orientation, Weld Lines. And tensile Strength have Relationship, see graph below.

These results show the importance of gate location and the need for the product

designer to coordinate his efforts with the tool builder. The gate should be located

both to avoid weld lines in high stress areas and to take full advantage of glass fiber reinforcement. Techniques the designer might use to reduce stress level at a weld line include increasing the wall thickness or adding ribs.

Solution

- This can be done by changing the polymer injection location or altering wall thicknesses to set up a different fill time.

- increasing mold temperature, melt temperature, injection rate and pressure.

- Increased mold venting or addition of flow tabs also can help turn a bad weld into

a good weld

- Change the gate positions.

- Change the part thickness.

- Optimize runner system design. Reduce runner dimensions and maintain the same flow rate to use shear heating to increase the melt temperature at the flow front

- Instead, it often helps to increase the injection velocity, decrease the fill time, and increase the shear rate, which can lower the viscosity of the polymer during fill and thereby allow for better chain entanglement and better packing. Increasing pack or hold pressure also helps, as well as having longer pack and hold times. Increasing pack or hold pressure helps to eliminate low-pressure conditions at the weld line. Another tactic to promote more chain entangling at the weld line is to raise the mold temperature 10° C (20° F).

Wednesday, March 3, 2010

Troubleshooting short shot problems on injection mold

The term "short shot" or "short mold" is used to refer to a phenomenon where plastic being injection molded does not reach certain portions of the inside of the die before solidifying. or it means that not enough resin has flowed into the mold to fill it adequately. The main causes for short shot are the mold condition or flowability problems with the resin. The problem is alleviated when a greater volume of resin flows more easily.

To ensure the finished part is of good quality, the part must also be adequately packed with plastic. Therefore the question to ask is not only, ""Will the part fill?"" but also, ""Can a good quality part be made?""

Some of the typical factors affecting this type of problem are as follows:

- Fluidity and viscosity characteristics of the plastic

- mold design (Flow restrictions. Due to channels freezing or inadequate runner design. gate design, bushing construction for ribs and bosses, the presence of venting, .)

- Hesitation and long or complex flow paths.

- Inadequate venting. Back pressure due to unvented air traps can cause a short shot.

- Molding machine performance (Including an empty hopper, blocked feed throat, or a worn non-return (check) valve that causes loss of pressure or volume leakage.)

picture above i copy from UMgabs.com, those check point is very important for troubleshooting short shot problems

Solution

- Eliminate air traps. If air traps do exist, they should be positioned in areas that can be easily vented or ejection pins added so that air can be removed.

- if Resin flows too slowly, Increase temperature in the cylinder. Increase injection speed. If no change in the filling time is noticed after setting of a high injection rate, there is a possibility that the performance of the molding machine is insufficient or that there is excessive pressure loss in the sprues, runners, and gates

- check resin viscosity, Increase the mold temperature.This will decrease the viscosity of the melt, making it easier for the plastic to flow through the part.

- Increase ram speed. This can cause greater shear heating, which decreases the viscosity of the melt, making it easier for the plastic to flow through the part.

- Increase the sectional area of the gate, sprue and runner, and shorten the length. Make the sprue, runner and gate surfaces more slippery.

- Change the gate position, increase the thickness of the mold cavity, modify design to improve flow.

- Change the part geometry. Balance flow paths so they fill in an equal time and an equal pressure. You may need to thicken thin sections, or reduce the complexity of a flow path.

- Use a different material. Select a less viscous material (higher melt flow rate). By choosing a material with a higher melt flow rate, less injection pressure will be required to fill the part.

To ensure the finished part is of good quality, the part must also be adequately packed with plastic. Therefore the question to ask is not only, ""Will the part fill?"" but also, ""Can a good quality part be made?""

Some of the typical factors affecting this type of problem are as follows:

- Fluidity and viscosity characteristics of the plastic

- mold design (Flow restrictions. Due to channels freezing or inadequate runner design. gate design, bushing construction for ribs and bosses, the presence of venting, .)

- Hesitation and long or complex flow paths.

- Inadequate venting. Back pressure due to unvented air traps can cause a short shot.

- Molding machine performance (Including an empty hopper, blocked feed throat, or a worn non-return (check) valve that causes loss of pressure or volume leakage.)

picture above i copy from UMgabs.com, those check point is very important for troubleshooting short shot problems

Solution

- Eliminate air traps. If air traps do exist, they should be positioned in areas that can be easily vented or ejection pins added so that air can be removed.

- if Resin flows too slowly, Increase temperature in the cylinder. Increase injection speed. If no change in the filling time is noticed after setting of a high injection rate, there is a possibility that the performance of the molding machine is insufficient or that there is excessive pressure loss in the sprues, runners, and gates

- check resin viscosity, Increase the mold temperature.This will decrease the viscosity of the melt, making it easier for the plastic to flow through the part.

- Increase ram speed. This can cause greater shear heating, which decreases the viscosity of the melt, making it easier for the plastic to flow through the part.

- Increase the sectional area of the gate, sprue and runner, and shorten the length. Make the sprue, runner and gate surfaces more slippery.

- Change the gate position, increase the thickness of the mold cavity, modify design to improve flow.

- Change the part geometry. Balance flow paths so they fill in an equal time and an equal pressure. You may need to thicken thin sections, or reduce the complexity of a flow path.

- Use a different material. Select a less viscous material (higher melt flow rate). By choosing a material with a higher melt flow rate, less injection pressure will be required to fill the part.

Friday, February 19, 2010

Stripper Ejector Construction (step by step mold design) part 8 : add return pin

In ejector system, return pin is important, i was post about ejector system, include the function of each part, see it at this link, previous post is adding ejector pin and ejector guide bush in the mold, now next step is adding return pin, when we use mold standard or mold base blank, return pin always include in those mold base blank, if you have the catalog, return pin symbol is always RP, with dimension from X direction and Y direction, see picture below, yellow pin is return pin.

picture below is standard mold base, i get from Lun Kee mold base standard we can show dimension of mold base standard 150 mm x 150 mm with flange 200 mm, return pin diameter 12 mm, with the position 57 in Y direction from 0,0. and 24 in X direction, see the green line at picture below

add the return pin between ejector plate, and ejector stripper plate, the height of return pin same with surface of core plate. make hole in Ej. plate and core plate. like picture below

Spring for Return Pin

this spring will help move back ejector plate and ejector stripper plate after ejecting process, by calculate load of ejector system we can choose the best spring for return pin, too hard spring will difficult to assembly, but too weak spring will give some problem in ejecting process, this spring also help to prevent ejector stuck after ejecting process. see the construction like picture below

some mold designer prefer make hole of spring until half of core plate. which one do you use it depend on load calculation of spring.

Next step are add ejector rod and support pillar

To prevent large deflection in center of cavity plate, we must add support pillar as much as we can, arrange it so the deflection of cavity mold when plastic injecting is minimum, deflection can make gap between cavity plate and core plate, so flashing maybe appear, maximum allowable deflection depend on material, but generally it about 20-30 micron.

In this case I put 4 support pillar symmetrically

To move ejector system, we must add ejector rods, in little mold generally use only 1 pcs of ejector rods until 80 ton still save use only 1 pcs. but if your construction more than 100 ton or mold base size more than 400 mm x 400 mm use more than one pcs of ejector rods.

picture below shown 1 pcs construction of ejector rods.

picture below is standard mold base, i get from Lun Kee mold base standard we can show dimension of mold base standard 150 mm x 150 mm with flange 200 mm, return pin diameter 12 mm, with the position 57 in Y direction from 0,0. and 24 in X direction, see the green line at picture below

add the return pin between ejector plate, and ejector stripper plate, the height of return pin same with surface of core plate. make hole in Ej. plate and core plate. like picture below

Spring for Return Pin

this spring will help move back ejector plate and ejector stripper plate after ejecting process, by calculate load of ejector system we can choose the best spring for return pin, too hard spring will difficult to assembly, but too weak spring will give some problem in ejecting process, this spring also help to prevent ejector stuck after ejecting process. see the construction like picture below

some mold designer prefer make hole of spring until half of core plate. which one do you use it depend on load calculation of spring.

Next step are add ejector rod and support pillar

To prevent large deflection in center of cavity plate, we must add support pillar as much as we can, arrange it so the deflection of cavity mold when plastic injecting is minimum, deflection can make gap between cavity plate and core plate, so flashing maybe appear, maximum allowable deflection depend on material, but generally it about 20-30 micron.

In this case I put 4 support pillar symmetrically

To move ejector system, we must add ejector rods, in little mold generally use only 1 pcs of ejector rods until 80 ton still save use only 1 pcs. but if your construction more than 100 ton or mold base size more than 400 mm x 400 mm use more than one pcs of ejector rods.

picture below shown 1 pcs construction of ejector rods.

Saturday, January 30, 2010

Stripper Ejector Construction (step by step mold design) part 7

Ejector Guide Pin and Bush

in this part, we will design ejector guide pin, EGP bush, bolts for stripper plate and bottom plate. first learn ejector system and part at link below

3D ejector drawing

hope you can understand ejector system and ejector guide pin (EGP) function, Ejector guide pin located between ejector plate and ejector stripper plate, to fit the ejector pin, we can add bolt at the bottom of EGP, and clamp it in bottom plate of mold

Bolt for spacer block

To make position of spacer block fit between backing support plate or core plate and bottom plate, add bolts from bottom plate to spacer block, see picture below for more detail. In each spacer block, add 2 pcs of bolts, the other function is when disassembling process spacer block and bottom plate became one part, it make dissembling easier

Ejector Puller Bolts

to push the stripper plate when ejecting proses begin, we need connector from ejector plate to stripper plate at core,in this case, i use ejector puller bolts, you also can use other standard part,just make sure that you can connect ejector plate to stripper plate at core side. see picture below for detail construction.

in this part, we will design ejector guide pin, EGP bush, bolts for stripper plate and bottom plate. first learn ejector system and part at link below

3D ejector drawing

hope you can understand ejector system and ejector guide pin (EGP) function, Ejector guide pin located between ejector plate and ejector stripper plate, to fit the ejector pin, we can add bolt at the bottom of EGP, and clamp it in bottom plate of mold

Bolt for spacer block

To make position of spacer block fit between backing support plate or core plate and bottom plate, add bolts from bottom plate to spacer block, see picture below for more detail. In each spacer block, add 2 pcs of bolts, the other function is when disassembling process spacer block and bottom plate became one part, it make dissembling easier

Ejector Puller Bolts

to push the stripper plate when ejecting proses begin, we need connector from ejector plate to stripper plate at core,in this case, i use ejector puller bolts, you also can use other standard part,just make sure that you can connect ejector plate to stripper plate at core side. see picture below for detail construction.