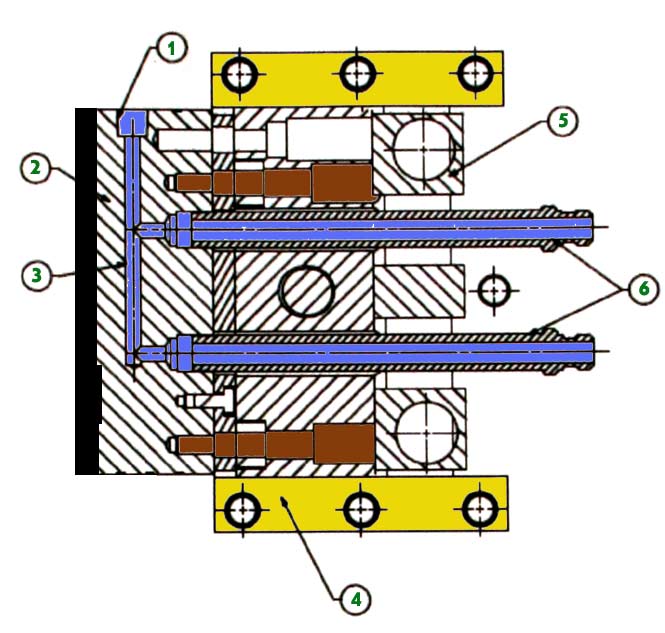

insert function

there are two function in of insert in this mold construction

1. to provide re change part, if the bowl shape doesn't good, we don't need to change all core side, but only the insert part. so this system is more cheaper when the part need good shape and good tolerance.

2. provide gas vent, and stripper construction, because the product need gas vent in bottom the side, and gas vent in stripper is not good, gas vent only can make with insert in core.

below is construction of insert part

Gas Vent Dimension and construction

gas vent can divide into 2 part, the accurate tolerance and not accurate tolerance part, the dimension of accurate tolerance is depending from plastic material that injected in molding, but generally is about 0,005 mm until 0,020 mm

Collar

at the end of insert part, there was a collar to prevent part move in Z axis, the dimension of collar is about diameter + 2mm and height is 4 mm