A mold plate is any plate required to built a complete mold, in all plate use for molds have the main requirements, they are :

1. Good corrosion resistant

2. Good Machinability.

3. Easy to clean

3. Good heat transfer.

4. Homogeneity of steel.

5. Easy ability.

6. Low Cost.

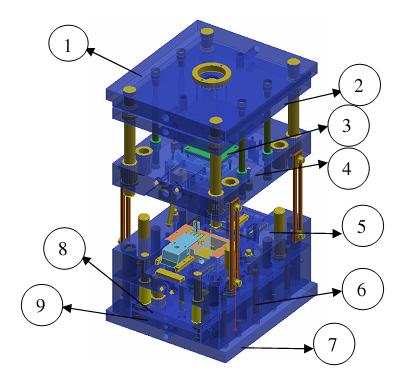

at picture below you can see 3 plate mold base type with closed position, basically 3 plate type and 2 plate type has some main plate, see explanation about

mold construction type to understand more,

explanation below based on number at those picture

1.

Fixed Clamping Plate or Top PlateHolds The fixed side of the mold to attached at the fixed platen of the injection machine. at this plate will attach locating ring, eye bolt, and sprue bush.

2.

Runner Stripper Platethis plate only used in 3 plate molds type, the function is to cut resin from nozzle in top of sprue bush, and pull the runner by runner locking pin.

3.

Fixed Mold Plate or Cavity plate.use to hold cavity side of product, leader pin, support pin, Puller bolts, and Angular pin when

slider attached.

4.

Movable Cavity Plate or Cavity plateit used to attach core side of product, return pin, leader bush and slider core if needed.

5.

Back up Plate or Support plateused to support cavity plate, attach the hole for return pin's spring, and cooling channel when in cavity plate can not make it.

6.

Spacer BlockMounted between the movable clamping plate (bottom plate) and the movable cavity plate to give space and allow the ejector plate to move when ejecting the

part. the required length of spacer block depend on ejector stroke that needed to eject product.

7.

Ejector retainer plateto hold the ejector, Z pin, shoulder bolts,and give space to ejector leader pin and support pillar.

8.

Ejector PlatePushes the ejector pins and return pins, connected with ejector rods.

9.

Movable Clamping Plate or Bottom plateHolds The movable side of the mold like spacer block, support plate, cavity plate and ejector mechanism to the movable platen of the injection machine.

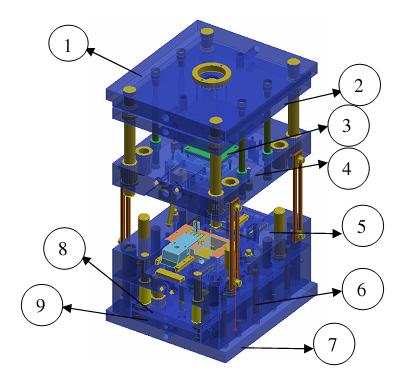

and look at picture below, shown 3 plate molds type in opening position, but at picture below, Bottom plate or movable clamping plate is number 7, number 8 is ejector retainer plate, and number 9 is ejector plate.