previous post

http://mould-technology.blogspot.com/2008/08/main-construction-pin-at-3plate-mold.html we can see closed condition of three plate molds

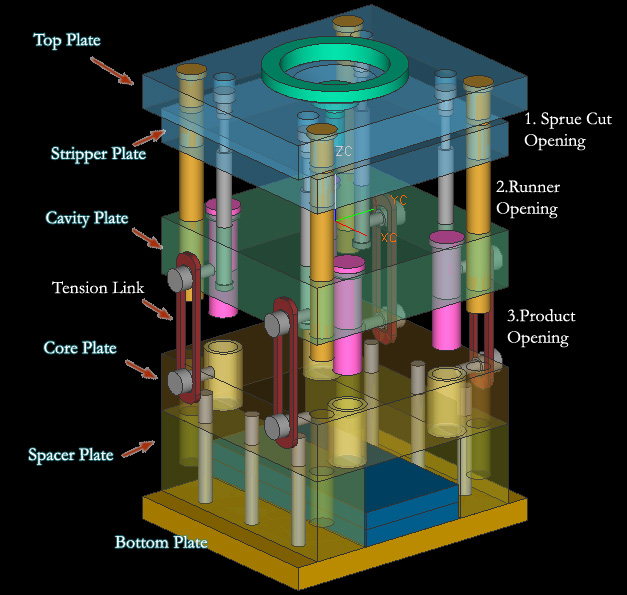

picture below is shown three plate condition when open

basically there are three opening type in 3 plate molds base

1. Sprue Cut Opening

2. Runner Opening

3. Product Opening

below i try to explain in simple words

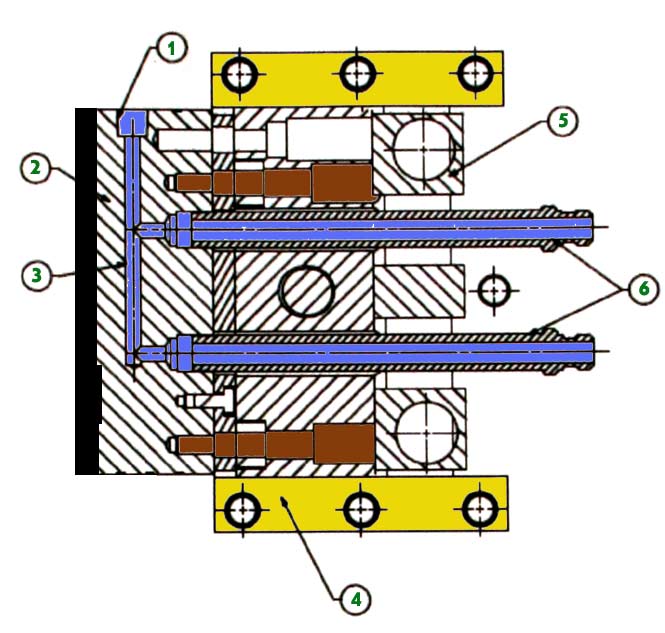

1. sprue cut openingthis opening will cut sprue from nozzle, so the feeding runner can take easily by arm robot or manually by hand, this opening use puller bolt and runner stripper plate to cut the sprue. the stripper plate will move after puller bolts pulled by cavity plate, remember that puller bolts also end mounted in cavity plate.

the opening length between 5mm until 10mm.

2. runner openingthis opening use tho open runner system, than runner will take by robot or manually,this opening will make space between stripper plate and cavity plate.

to make sure this runner opening safely, attach spring in puller bolts between stripper plate and cavity plate, or use other methods like attach spring in out of puller bolts. length of this opening is same with runner length + 20 mm.

3. product opening, as we know this opening is to open the product, make space so the product can be ejected from core.

this opening length is about length the product + length robot arm + 10 until 20 mm to make save space when product ejected.

Opening Sequenceactually to pull the cavity plate, so the cavity plate can pull the puller bolts than open the stripper plate have two types, using tension link and magnet.

OK, at this post let's learn when using tension link.

1. first Opening is Runner Opening

why ? becouse between stripper plate and cavity plate,some springs always attached at there, some mold designer attach at puller bolts, and the other attach in each side using pin and make some hole to attach the spring. but i prefer attach the spring in puller bolts, it more easy in process.(sorry at picture above i don't write some spring)

2. Second Opening is Product Opening

Parting Line between core - cavity plate always easy to open, when moving plate at the injection machine pull the bottom plate until core plate, it will make Product Opening open.

3. Sprue Cutting Opening

after moving plate pull the core plate, with tension link core plate will pull the cavity plate until cavity plate pull the puller bolt, and make some space to cut the sprue from nozzle.