This model is widely used for large parts and molds with a tonnage greater than 350 tons, other advantage is the size of the mold base to be more compact and small, so the cost for the mold base can also be reduced, and if the size is smaller base can mold into tonnase also smaller

Showing posts with label slider parts. Show all posts

Showing posts with label slider parts. Show all posts

Wednesday, December 22, 2010

using mold base become locking block of slider unit

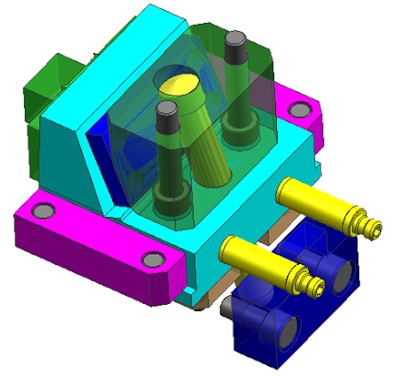

moldbase sometimes can be used for the locking block on the slider unit, this is basedon several reasons, for example, to reduce cost, by reducing the insert locking block, the other reason is required surface area for the locking block.

illustration picture above shows the angular pins are bolted to the mold base and the mold base made pocket instead of locking block,

to keep the process easy to do maintenance, should be installed oil slide plate, so when it can wear easily replaced without the need to change their plate slider block.

This model is widely used for large parts and molds with a tonnage greater than 350 tons, other advantage is the size of the mold base to be more compact and small, so the cost for the mold base can also be reduced, and if the size is smaller base can mold into tonnase also smaller

This model is widely used for large parts and molds with a tonnage greater than 350 tons, other advantage is the size of the mold base to be more compact and small, so the cost for the mold base can also be reduced, and if the size is smaller base can mold into tonnase also smaller

Monday, August 2, 2010

Locking Block With Angular Slider

3:53 PM

Mold Construction, mold design, slider parts

What should you do when the slider design and found that the angular slider too long? There are many ways to change the design so that the angular length of the slider pins are still reasonable when compared to its diameter.in design between the angular diameter and length of the slider pins should be noted, the length of angular slider pins that are too long can lead to easily broken when the mass production run, especially if the small angular diameter, the way the installation is also a concern to be easy in the process of repair when damage occurs.

the above picture, I took when designing the angular pin slider, when the client wants the angular pin slider must exist, and based on the calculation of stroke, it turns out the angular pin length is too long, surely this is dangerous and i should change the design concept.

other than dangerous, the above design concept is also difficult in maintenance because if the angular pin broke the mold base must be dropped from the injection machine, disassembly the mold then can be replaced, this is because the angular pin must be in pairs from the top plate embedded in the cavity

Locking Block With Angular Slider

This design concept in addition to saving space, saving the long angular slider also has the advantage of easy installation and maintenance, although the angular pin mold was broken when used for production, the mold does not need to send down from the injection machine to replace it. look at picture below

on the design concept above, I only use one bolt to tighten to the cavity plate, simple but I'm sure I could save the angular length of approximately half of the angular slider before. The above concept also facilitates the repair process.

The second alternative was similar, but the difference is the number of bolts are used and how big a part of the locking block affixed to the cavity plate, the first altenative collar only are plugged into the cavity plate, and the bolts, of course, only part that holds the slider in the section just the collar. A second alternative is different from all bagianya embedded in the plate cavity.

I chose the second alternative concept, the concept was made 3D and 2D drafting calculations based on a stroke, for details, under the following 3D image is the result of the 3D design of the second alternative.

Saturday, June 26, 2010

slider construction : cam or angular pin

11:34 AM

Mold Construction, slider parts

posts related to construction and part-bagianya slider has been my post, about the cooling on the slider, the basic construction for the slider, the slider and the main part, please see previous post to learn the basic construction and when we should use the slider, This post will discuss about when we need to use of the slider that use angular pin or just cam slider, what advantages and disadvantages of both types of construction such slider.

ANGULAR PIN

basically, the type of construction of the slider based on how to pull out the core slider is divided into three types, first use the angular pin,using the force of the angular pin at a certain angle, the slider block would be pull out, the second is a cam slider, just use the thrust of the spring and stopper on the slider, and calculating a stroke, cam slider allows you to easily pull the slider core, the third is the use of hydraulic or pneumatic system to pull the slider core, specifically for the third way is needed so that movements of individual controls in accordance when the slider open mold and mold close.picture below shows slider with angular pin system.

picture above shown standard complete construction for slider, it's include cooling plug, stopper (blue color), adjustment plate between locking block and slider core(blue), guide rel (pink) etc. angular pin system very common use in slider system, Angular sometimes do not have a round pin, shape the box is also commonly used, actually used the same angle, both will be used by considering the strength, structure, mold, and the available space.

The advantage is the use of angular pins can be used for parts that have undercut short or long, easy to maintain when the angular broken, just enough to change the angular pin. inexpensive in manufacture, and can be used for long-stroke slider to medium, the angular pin length has not touched bottom plate.

for instance,look at picture above if undercut wide for most of the parts, use the slider two pins with a diameter sufficient, then you will get a strong slider construction and safe.

CAM SLIDER

while the slider does not require angular cam pin, the cam slider there are several types of commonly used, the clamp type, two angle type, cam units type and one direction cam. because in using the cam to take calculation of a stroke is used, why?? it's to prevent slider core not be separated from the locking block, and the strength of the spring, so that true core slider can move and hit the stopper. cam slider can only be used for minor stroke (0.5 mm-5mm), small undercut, and not too wide undercut form.

a benefit is a cam slider can be used for high cycle time, mold construction, saving space, and easy assembly.

whereas the less than the limited form that can be undercut in the form, was difficult in the manufacture and maintenance.

ANGULAR PIN

basically, the type of construction of the slider based on how to pull out the core slider is divided into three types, first use the angular pin,using the force of the angular pin at a certain angle, the slider block would be pull out, the second is a cam slider, just use the thrust of the spring and stopper on the slider, and calculating a stroke, cam slider allows you to easily pull the slider core, the third is the use of hydraulic or pneumatic system to pull the slider core, specifically for the third way is needed so that movements of individual controls in accordance when the slider open mold and mold close.picture below shows slider with angular pin system.

picture above shown standard complete construction for slider, it's include cooling plug, stopper (blue color), adjustment plate between locking block and slider core(blue), guide rel (pink) etc. angular pin system very common use in slider system, Angular sometimes do not have a round pin, shape the box is also commonly used, actually used the same angle, both will be used by considering the strength, structure, mold, and the available space.

The advantage is the use of angular pins can be used for parts that have undercut short or long, easy to maintain when the angular broken, just enough to change the angular pin. inexpensive in manufacture, and can be used for long-stroke slider to medium, the angular pin length has not touched bottom plate.

for instance,look at picture above if undercut wide for most of the parts, use the slider two pins with a diameter sufficient, then you will get a strong slider construction and safe.

CAM SLIDER

while the slider does not require angular cam pin, the cam slider there are several types of commonly used, the clamp type, two angle type, cam units type and one direction cam. because in using the cam to take calculation of a stroke is used, why?? it's to prevent slider core not be separated from the locking block, and the strength of the spring, so that true core slider can move and hit the stopper. cam slider can only be used for minor stroke (0.5 mm-5mm), small undercut, and not too wide undercut form.

a benefit is a cam slider can be used for high cycle time, mold construction, saving space, and easy assembly.

whereas the less than the limited form that can be undercut in the form, was difficult in the manufacture and maintenance.

Thursday, January 24, 2008

Mold Cooling Design at Slider

Why mold need cooling ? as we know that cooling conditions affect cycle time, part dimensions, surface finish, and warpage, Mold cooling time is the biggest contributor to the overall cycle time, it could be as two-thirds or 70-80% of total cycle time.

from those reason design an efficient cooling circuit can reduces the cooling time, beside that uniform cooling improve part quality by reducing residual stress, stability of heat transfer, and accuracies of part after cooled.

Why Slider Need Cooling?

Some product have long dimension that need slider, to prevent warpage, residual stress, and stability of shrinkage behavior, for that reason slider need cooling.

Mold Cooling Construction

picture below shown cooling construction at slider insert from top side.

annotation number at picture upper indicate part of slider, they are

1. Plug

2. Slider Insert

3. Cooling Pipe

4. Guide Rel of slider core

5. Locking Block slider

6. Long Nipple

Pipe with blue color indicate flow of water when cooling process working. number 1 part (Plug) prevent water flow to side of slider inserts.

When design nipple,make sure that nipple is long enough to reach outer side of mold base.

to get understand more look at picture below, at this picture still shown cooling at slider from left side.

additional number of slider parts are

7. slider core (this part is one of slider main part, where slider insert attached)

8. Angular slider ( the main function of angular is change the moving 90 degree, so slider can move)

from those reason design an efficient cooling circuit can reduces the cooling time, beside that uniform cooling improve part quality by reducing residual stress, stability of heat transfer, and accuracies of part after cooled.

Why Slider Need Cooling?

Some product have long dimension that need slider, to prevent warpage, residual stress, and stability of shrinkage behavior, for that reason slider need cooling.

Mold Cooling Construction

picture below shown cooling construction at slider insert from top side.

annotation number at picture upper indicate part of slider, they are

1. Plug

2. Slider Insert

3. Cooling Pipe

4. Guide Rel of slider core

5. Locking Block slider

6. Long Nipple

Pipe with blue color indicate flow of water when cooling process working. number 1 part (Plug) prevent water flow to side of slider inserts.

When design nipple,make sure that nipple is long enough to reach outer side of mold base.

to get understand more look at picture below, at this picture still shown cooling at slider from left side.

additional number of slider parts are

7. slider core (this part is one of slider main part, where slider insert attached)

8. Angular slider ( the main function of angular is change the moving 90 degree, so slider can move)

Sunday, November 18, 2007

When we need slider parts in Mold Design

second previous post i have post about the slider parts and construction in complete mold base , then now i give a little brief when we need slider in mold design, basically we design mold from our customer, first is we must look the parts that we will make by plastic mold, look mare at the drawing so we can know about tolerance and critical point of parts, seconds is define the parting line, first parting line is between core and cavity parts, and after that if the parts have side form we must define slider parting line, look picture below

from those parts we know that we need slider parts, side hole and other shape that can not form by core and cavity became slider parts. below is picture in 3D modeling,look at the hole shape in side, those shape need slider part.

and how the construction of slider, more about construction mold you can see by clicking mold construction or molds parts in quick topic, basically here i give slider 3D modeling and parts name, those parts names i take from Misumi standard mold design

you can use this tutorial for education and others purpose but still write copyright from this site.

from those parts we know that we need slider parts, side hole and other shape that can not form by core and cavity became slider parts. below is picture in 3D modeling,look at the hole shape in side, those shape need slider part.

and how the construction of slider, more about construction mold you can see by clicking mold construction or molds parts in quick topic, basically here i give slider 3D modeling and parts name, those parts names i take from Misumi standard mold design

you can use this tutorial for education and others purpose but still write copyright from this site.

Sunday, November 11, 2007

Slider Design and Basic Construction

picture below show slider basic construction in Mold, various construction and litle part available in slider but the basic construction of slider is same, look picture below, sorry if this picture is too grainy, i'll make a new one.

the main part from those picture is mold plate, number 1 until 10 is shown the plate of mold

plate 1 is top plate

plate 2 is gate opener plate, retainer plate, and others name depend in fabrics

plate 3 is cavity plate

plate 4 is core plate

plate 5 is backing plate

plate 6 is support plate

plate 7 is ejector plate

plate 8 is ejector retainer plate

plate 9 is bottom plate

plate 10 is runner plate

and the slider part name are

g for angular pin, this pin always have certain degree, usually between 10-30, angular pin will transfer vertical movement to horizontal movement, others construction, angular pin not from the top but from bottom, this kind of construction is rare to use now.

h is slider core, when contact with angular pin, this part also the core from slider construction, at this part we can attach insert part that mold the shape of plastic.

i is slider locking block, we can depend in angular pin when mold closed, slider pin is too week, so the holder of pressure from inside mold during injection process is locking block.

k is slider lock plate, for non mass production you do not have to attach this part, but if the mold used in mass production, i suggest to use this part, because slider locking block and slider core always have friction, then when this part broken or got abrasive is will need expensive cost to repair it, so use lock plate is better, is cheaper.

l(L) is slider insert, this part which form the plastic product, it's attach in slider core

the main part from those picture is mold plate, number 1 until 10 is shown the plate of mold

plate 1 is top plate

plate 2 is gate opener plate, retainer plate, and others name depend in fabrics

plate 3 is cavity plate

plate 4 is core plate

plate 5 is backing plate

plate 6 is support plate

plate 7 is ejector plate

plate 8 is ejector retainer plate

plate 9 is bottom plate

plate 10 is runner plate

and the slider part name are

g for angular pin, this pin always have certain degree, usually between 10-30, angular pin will transfer vertical movement to horizontal movement, others construction, angular pin not from the top but from bottom, this kind of construction is rare to use now.

h is slider core, when contact with angular pin, this part also the core from slider construction, at this part we can attach insert part that mold the shape of plastic.

i is slider locking block, we can depend in angular pin when mold closed, slider pin is too week, so the holder of pressure from inside mold during injection process is locking block.

k is slider lock plate, for non mass production you do not have to attach this part, but if the mold used in mass production, i suggest to use this part, because slider locking block and slider core always have friction, then when this part broken or got abrasive is will need expensive cost to repair it, so use lock plate is better, is cheaper.

l(L) is slider insert, this part which form the plastic product, it's attach in slider core