Showing posts with label mold cooling. Show all posts

Showing posts with label mold cooling. Show all posts

Saturday, April 7, 2012

rapid heat cooling system on injection mold

rapid heat temperature, is actually an old method that is often used to eliminate the weld line, the front cover products such as TV, is an example of the most frequently used method, but its use is now developed further, as demand for products with low cycle time and quality of surface nice sharp increase lately, covering progress being made is that the control system is used, so the heat on the heating rod is held constant, the only heating occurs during the process of filling, so filling process stops, and the cooling process is done, no heating rod heating process.

Trim cycle times up to 20 %

A new unit combines rapid heating and cooling and mold-temperature control in one unit as a means to trim cycle times by up to 20% and reduce energy cost. It is the result of a collaboration between Wieder GmbH International of Germany, a supplier of pulsed mold heating/cooling systems, and Regloplas of Switzerland, a maker of fluid temperature-control units

Reduce Weld line

because during the process of filling, the mold is heated, especially at the regional meeting of the plastic, this led to the solidification of the material evenly, so that the weld line can be minimized.

injection mold is rapidly heated to a high temperature, usually higher than the glass transition temperature of the polymer material, before melt-injection and rapidly cooled down to solidify the shaped polymer melt in mold cavity for ejection. Since the elevated mold temperature can eliminate the unwanted premature melt freezing during filling stage, the melt flow resistance is greatly reduced and the filling ability of the polymer melt is also significantly improved. As a result, plastic parts with excellent surface appearance can be obtained.

Improve Appearance

rapid heat cycle method is also shown to improve the quality of the surface, this is because the process of filling with stable temperatures ranging from the gate to the end product, or it could be said to be due to differences in temperature in the cavity is not much different.

Reduce Cost

I was not sure whether this method can reduce the cost of production, when production is carried out is to a large scale, of course, 10-20% reduction in cycle time will bring a lot of meaning to the cost of production, but when the scale of SMEs, given the initial price for the application of this method expensive, I think this method will not reduce production costs.

various types of heating methods research has been carried out

1. use of the insulation layer, An insulation layer is coated onto the mold base then a heating layer is applied to the insulation layer as the cavity surface, for Increasing the mold surface temperature in the filling process, a coating on the cavity surfacewith TiN and Teflon has reduced the heat transfer from the melt to the mold material, the which Increased the temperature on the cavity surface.

2. the use of steam. difficulty of this method is the first installation costs are expensive, and slow increase in temperature,

3. Infrared radiation on the surface, this method has also been investigated, and are able to reduce cycle time by 20%

4. electric heating rod, this method is the method most commonly used in industry because of the installation, maintenance, repairs are relatively easy. but the price per Kw electricity is relatively expensive, because it takes a minimum of 300 watts for a heating rod.

Reference

1. S.C. Chen, H.S. Peng, J.A. Chang, W.R. Jong, Simulation and verification of induction

heating on a mold plate, International Communications in Heat and Mass Transfer

31 (7) (2004) 971–980.

2. P.C. Chang, S.J. Hwang, Simulation of infrared rapid surface heating for injection

molding, International Journal of Heat and Mass Transfer 49 (21–22) (2006)

3846–3854.

3. G.L. Wang, G.Q. Zhao, H.P. Li, Y.J. Guan, Research of thermal response simulation

and mold structure optimization for rapid heat cycle molding process,

respectively, with steam heating and electric heating, Materials and Design 31

(1) (2010) 382–395.

4. X.P. Li, G.Q. Zhao, Y.J. Guan, M.X. Ma, Optimal design of heating channels for rapid

heating cycles injection mold based on response surface and genetic algorithm,

Materials and Design 30 (10) (2009) 4317–4323.

Friday, March 23, 2012

Cooling Layout and Cooling method between core/cavity and mold base

Cooling is most important parameter when talking about cycle time reduce, some of my friend who very interest in injection mould still confuse how to design cooling system in injection mould, before talking about optimal design, first we must be familiar with the term and design standard that will be used.

Basic Cooling Layout

in principle, the more uniform temperature in the cavity, the better the resulting product, the more uniform and rapid heat transfer processes during the process of solidification occurs, the faster the cooling process, and of course the faster the cycle time that happened.when designing, to keep the cooling process is rapid and uniform cooling channels should be sought closer to the wall of the product, especially for regions of high and thick walls. therefore the cavity cooling channels is essential.

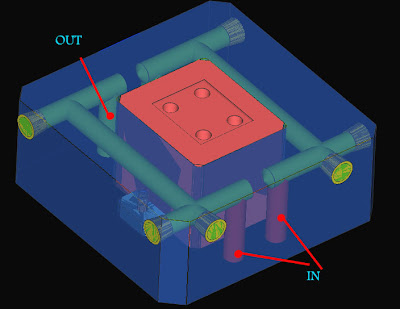

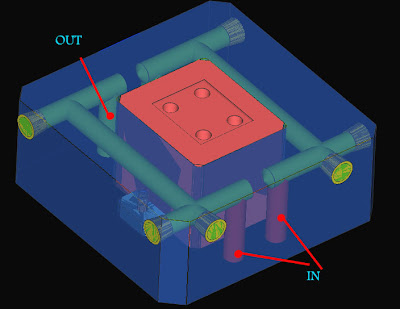

in the image above, is an example of basic connections cooling layout, its parts are

A. cavity colored with blue

2. green is mold base

3. yellow is cooling joint plug

4. white is hose connection to connecting cooling joint plug

on the left side of mold in above picture, we see that two pcs of cooling joint plug (yellow color) in that side, is for input and output of cooling mold base and cooling channel from the machine.

Rectangle Like Layout

depend one cooling layout is a favorite around the product, because the drilling process should be straight, then the shape is rectangle, except in the form of circular gear will be retained.

Basic Cooling Layout

in principle, the more uniform temperature in the cavity, the better the resulting product, the more uniform and rapid heat transfer processes during the process of solidification occurs, the faster the cooling process, and of course the faster the cycle time that happened.when designing, to keep the cooling process is rapid and uniform cooling channels should be sought closer to the wall of the product, especially for regions of high and thick walls. therefore the cavity cooling channels is essential.

in the image above, is an example of basic connections cooling layout, its parts are

A. cavity colored with blue

2. green is mold base

3. yellow is cooling joint plug

4. white is hose connection to connecting cooling joint plug

on the left side of mold in above picture, we see that two pcs of cooling joint plug (yellow color) in that side, is for input and output of cooling mold base and cooling channel from the machine.

Rectangle Like Layout

depend one cooling layout is a favorite around the product, because the drilling process should be straight, then the shape is rectangle, except in the form of circular gear will be retained.

Saturday, July 26, 2008

Sprue bush cooling design and construction

some times sprue bush need cooling to cut the cycle time of injection process, when diameter of sprue is large cooling in sprue bush is important. some fabrication of mold part have their own sprue bush that containing cooling pipe. like picture below

from those picture some standard part mold company have their own methods to make inner cooling at the sprue bush, we can by cutting in some part that weld together again, or by other method.

the other way to make cooling in sprue is like picture below

by those type of sprue we change the entrance and exit flow by using stopper buffle, for example like picture below

or you can make the flow straight, the other cooling method in sprue is like picture below, by using this type is easy to attach the O ring, becouse in and out flow from below side that contact with moldbase. becouse when assembling of ring to moldbase is more easy by attach the O ring in Moldbase then put the sprue bush than attach the O ring in sprue bush and assembling it together in moldbase.

from those picture some standard part mold company have their own methods to make inner cooling at the sprue bush, we can by cutting in some part that weld together again, or by other method.

the other way to make cooling in sprue is like picture below

by those type of sprue we change the entrance and exit flow by using stopper buffle, for example like picture below

or you can make the flow straight, the other cooling method in sprue is like picture below, by using this type is easy to attach the O ring, becouse in and out flow from below side that contact with moldbase. becouse when assembling of ring to moldbase is more easy by attach the O ring in Moldbase then put the sprue bush than attach the O ring in sprue bush and assembling it together in moldbase.

Sunday, June 22, 2008

Construction of Cavity Cooling and Mold Base Cooling, O ring

7:20 AM

cooling construction, Mold Construction, mold cooling, Mold part and construction

No comments

here the basic construction of joining cavity cooling and mold base cooling, we can use from simple construction to joint cavity and mold base cooling with one O ring, or we can use more complex construction like using special plate, and various O ring seal type. here is basic construction to joint the cavity cooling and mold base cooling.

both circular type and straight type cooling can be joint use those construction,

those construction use in half circular type of cooling system like picture below

click the image to see more large

simple joint just need one O ring or rubber seal, O ring pocket is preferred make in horizontal face from assembly, becouse it's make assembly and machining process mold more easily,

basic rule and tolerance to prevent leak in O ring are like picture below

at the cross section of cavity and mold base cooling construction, blue color indicate mold base part, and light yellow indicate cavity block, green is indicate hole or pipe of cooling. light black is O ring before penetrate with cavity block.

however is the simplest construction to join cooling cavity and mold base.

both circular type and straight type cooling can be joint use those construction,

those construction use in half circular type of cooling system like picture below

click the image to see more large

simple joint just need one O ring or rubber seal, O ring pocket is preferred make in horizontal face from assembly, becouse it's make assembly and machining process mold more easily,

basic rule and tolerance to prevent leak in O ring are like picture below

at the cross section of cavity and mold base cooling construction, blue color indicate mold base part, and light yellow indicate cavity block, green is indicate hole or pipe of cooling. light black is O ring before penetrate with cavity block.

however is the simplest construction to join cooling cavity and mold base.

Tuesday, June 17, 2008

Straight Type Cooling for Cavity

Basically cavity system cooling can divide into two type

1. straight type

2. Circular type

straight type system, usually have in and out of water pipe in not same side of mold or cavity. look at picture below

although the pipe that cool of insert part doesn't straight, but if inlet and outlet cooling fluid is not in same side we can consider that those type of cooling is straight. red color pipe indicate inlet and blue color pipe indicate outlet.

second picture below is still same with previous but this picture include the cavity block

yellow part at each side is plug to prevent unwanted flow of cooling, pink block at the center is core insert part. with attach to core block using bolt. Block with blue color is core block before inserted to mold base.

1. straight type

2. Circular type

straight type system, usually have in and out of water pipe in not same side of mold or cavity. look at picture below

although the pipe that cool of insert part doesn't straight, but if inlet and outlet cooling fluid is not in same side we can consider that those type of cooling is straight. red color pipe indicate inlet and blue color pipe indicate outlet.

second picture below is still same with previous but this picture include the cavity block

yellow part at each side is plug to prevent unwanted flow of cooling, pink block at the center is core insert part. with attach to core block using bolt. Block with blue color is core block before inserted to mold base.

Saturday, February 9, 2008

Paralel and series Cooling methode at flat type plate of Mold Base

almost mold designer know that cooling is biggest part that effect cycle time of injection mold, a good design in cooling will make heat exchange between resin after injected and mold will reduce cycle time and give good product.

at flat type of mold base plate like stripper (Plate number2) plate between top plate and cavity plate, top plate it self, and support plate after core plate, at the top plate cooling not always used, it very depend on resin type,and product shape.

the picture below shown some flat mold base that we can use parallel or series cooling methods

How about core and cavity of Mold base ?

we can use both type of cooling series and parallel when design cooling at core and cavity plate, but you must careful place the cooling, because beside cavity molds it self, they are ejector at the core plate then sprue and runner system at cavity plate. the construction and how to connecting cooling at mold plate with cavity mold cooling will discuss later.

Parallel Cooling Channel

picture below shown parallel cooling channels concept

basic mold base cooling have four parts, they are :

1. Main Cooling pipe

commonly cooling pipe make by drilling using bore,the longer drilled hole, it recommended have length about 6 mm if using long nipple joint to connect with outer tube, if using nipple or inner joint plug each cooling pipe minimum have 12 mm.

2. stopper plugs, like at slider cooling and cavity cooling stopper plugs is prevent water or oil coolant flow to undesirable way.

3. Inner stopper plugs, the function is same as stopper plugs, but assembly methods and location is different, it assembled at inner of cooling pipe.

parallel cooling channels are drilled straight trough supply manifold cooling pipe, due the parallel design flow characteristics, the flow rate along various cooling will different, because each cooling pipe have their own flow resistance. as a results, cooling of the mold will not uniform. so it's clear that parallel circuit of cooling in molds are very poor flow rates.

Series Cooling

picture below shown basic series cooling construction and methods

the parts is same with parallel cooling type, but the construction is different, at the series cooling channel types, it connected in single loop from the coolant inlet until its outlet, we can configure the flow by adjust the inner stopper plug type.

when design it is recommended to use same size of diameter cooling, because it's can maintain the turbulent flow, turbulent flow enables heat to be transferred more effectively.

Long and Shorts Nipple joint plug Assembly methods

considering mold base material strength,closer distance between two nipple plug type are not advisable, look at picture below

assembly between long type and shorts type is different, by using long type minimum length from both side is 6 mm, except for little diameter hole, less then 5 mm, smaller length spacing my be acceptable.

Short nipple joint types almost assembly in inner mold base, because of that minimum length space is 12,5 mm, although 10 mm my acceptable but will difficult to assembly it using hand.

at flat type of mold base plate like stripper (Plate number2) plate between top plate and cavity plate, top plate it self, and support plate after core plate, at the top plate cooling not always used, it very depend on resin type,and product shape.

the picture below shown some flat mold base that we can use parallel or series cooling methods

How about core and cavity of Mold base ?

we can use both type of cooling series and parallel when design cooling at core and cavity plate, but you must careful place the cooling, because beside cavity molds it self, they are ejector at the core plate then sprue and runner system at cavity plate. the construction and how to connecting cooling at mold plate with cavity mold cooling will discuss later.

Parallel Cooling Channel

picture below shown parallel cooling channels concept

basic mold base cooling have four parts, they are :

1. Main Cooling pipe

commonly cooling pipe make by drilling using bore,the longer drilled hole, it recommended have length about 6 mm if using long nipple joint to connect with outer tube, if using nipple or inner joint plug each cooling pipe minimum have 12 mm.

2. stopper plugs, like at slider cooling and cavity cooling stopper plugs is prevent water or oil coolant flow to undesirable way.

3. Inner stopper plugs, the function is same as stopper plugs, but assembly methods and location is different, it assembled at inner of cooling pipe.

parallel cooling channels are drilled straight trough supply manifold cooling pipe, due the parallel design flow characteristics, the flow rate along various cooling will different, because each cooling pipe have their own flow resistance. as a results, cooling of the mold will not uniform. so it's clear that parallel circuit of cooling in molds are very poor flow rates.

Series Cooling

picture below shown basic series cooling construction and methods

the parts is same with parallel cooling type, but the construction is different, at the series cooling channel types, it connected in single loop from the coolant inlet until its outlet, we can configure the flow by adjust the inner stopper plug type.

when design it is recommended to use same size of diameter cooling, because it's can maintain the turbulent flow, turbulent flow enables heat to be transferred more effectively.

Long and Shorts Nipple joint plug Assembly methods

considering mold base material strength,closer distance between two nipple plug type are not advisable, look at picture below

assembly between long type and shorts type is different, by using long type minimum length from both side is 6 mm, except for little diameter hole, less then 5 mm, smaller length spacing my be acceptable.

Short nipple joint types almost assembly in inner mold base, because of that minimum length space is 12,5 mm, although 10 mm my acceptable but will difficult to assembly it using hand.

Sunday, January 27, 2008

Cavity mold cooling construction design

In commonly mold designer know that Cooling conditions affect cycle time, part dimensions, surface finish, and warpage. but some junior mold designer still confuse to make layout and construction of cooling in mold.

before this posting, i havepost about cooling construction in slider, beside slider mold cavity also important to fill cooling, why because almost product 70-80 % is molded shape in mold cavity.

picture above shown core side of cavity mold, the basic construction is

1. Plug (Plug is for prevent water flow out from desire flow layout)

2. cooling pipe (as those picture cooling pipe doesn't shown, almost cavity cooling pipe processing using jig bor to make a long hole that becoming cooling pipe)

3. In / Out Hole, it's hole also make using jig bore. this hole will attach in cavity plat that will match with cooling layout in mold base.

orange color indicate product insert hole shape.

here i post basic construction in single cavity, see picture below to learn more

picture above is shown flow of cooling process of cavity mold from top view.

then which hole water flow in and flow out, see picture below

at this wireframe method picture, we should make hole at bottom side of core to connected cavity and cooling layout of mold base.

Tips Design Cooling pipe for cavity

1. make sure side of cooling pipe have enough length from insert, minimum 3 cm

2. choose a good diameter for the hole, like 6 cm, 8 cm, or 10 cm.

3. when injection proses begin make sure using calculation so you have turbulent flow in cooling pipe.

4. make the pipe more long is useful for make turbulent flow.

then how the layout and construction of cooling in mold base ?

just wait for new post

before this posting, i havepost about cooling construction in slider, beside slider mold cavity also important to fill cooling, why because almost product 70-80 % is molded shape in mold cavity.

picture above shown core side of cavity mold, the basic construction is

1. Plug (Plug is for prevent water flow out from desire flow layout)

2. cooling pipe (as those picture cooling pipe doesn't shown, almost cavity cooling pipe processing using jig bor to make a long hole that becoming cooling pipe)

3. In / Out Hole, it's hole also make using jig bore. this hole will attach in cavity plat that will match with cooling layout in mold base.

orange color indicate product insert hole shape.

here i post basic construction in single cavity, see picture below to learn more

picture above is shown flow of cooling process of cavity mold from top view.

then which hole water flow in and flow out, see picture below

at this wireframe method picture, we should make hole at bottom side of core to connected cavity and cooling layout of mold base.

Tips Design Cooling pipe for cavity

1. make sure side of cooling pipe have enough length from insert, minimum 3 cm

2. choose a good diameter for the hole, like 6 cm, 8 cm, or 10 cm.

3. when injection proses begin make sure using calculation so you have turbulent flow in cooling pipe.

4. make the pipe more long is useful for make turbulent flow.

then how the layout and construction of cooling in mold base ?

just wait for new post

Thursday, January 24, 2008

Mold Cooling Design at Slider

Why mold need cooling ? as we know that cooling conditions affect cycle time, part dimensions, surface finish, and warpage, Mold cooling time is the biggest contributor to the overall cycle time, it could be as two-thirds or 70-80% of total cycle time.

from those reason design an efficient cooling circuit can reduces the cooling time, beside that uniform cooling improve part quality by reducing residual stress, stability of heat transfer, and accuracies of part after cooled.

Why Slider Need Cooling?

Some product have long dimension that need slider, to prevent warpage, residual stress, and stability of shrinkage behavior, for that reason slider need cooling.

Mold Cooling Construction

picture below shown cooling construction at slider insert from top side.

annotation number at picture upper indicate part of slider, they are

1. Plug

2. Slider Insert

3. Cooling Pipe

4. Guide Rel of slider core

5. Locking Block slider

6. Long Nipple

Pipe with blue color indicate flow of water when cooling process working. number 1 part (Plug) prevent water flow to side of slider inserts.

When design nipple,make sure that nipple is long enough to reach outer side of mold base.

to get understand more look at picture below, at this picture still shown cooling at slider from left side.

additional number of slider parts are

7. slider core (this part is one of slider main part, where slider insert attached)

8. Angular slider ( the main function of angular is change the moving 90 degree, so slider can move)

from those reason design an efficient cooling circuit can reduces the cooling time, beside that uniform cooling improve part quality by reducing residual stress, stability of heat transfer, and accuracies of part after cooled.

Why Slider Need Cooling?

Some product have long dimension that need slider, to prevent warpage, residual stress, and stability of shrinkage behavior, for that reason slider need cooling.

Mold Cooling Construction

picture below shown cooling construction at slider insert from top side.

annotation number at picture upper indicate part of slider, they are

1. Plug

2. Slider Insert

3. Cooling Pipe

4. Guide Rel of slider core

5. Locking Block slider

6. Long Nipple

Pipe with blue color indicate flow of water when cooling process working. number 1 part (Plug) prevent water flow to side of slider inserts.

When design nipple,make sure that nipple is long enough to reach outer side of mold base.

to get understand more look at picture below, at this picture still shown cooling at slider from left side.

additional number of slider parts are

7. slider core (this part is one of slider main part, where slider insert attached)

8. Angular slider ( the main function of angular is change the moving 90 degree, so slider can move)