basically melted material is fed to this gate from a separate primary gate (after runner), the function of the gate typically is employed for flat and thin parts to reduce the shear stress in the cavity, Tab gate able to used in various material plastic such us ABS, PS, acrylic, PP, PVC, Polycarbonate. SAN and other which has relatively low fluidity. at this type of gate, the high shear stress generated around the gate that trimmed after molded. this gate sometimes also called the collision gate.

Function in Product and General Rule

The thickness of tab gate should be the same as the part wall, yo can also make more thin, but when designed parts for cosmetic parts if preferred that the thickness is same with the product thickness.

rule number two is, make the gate as center as possible in the product side, but you must consider the product size and shape.

basically minimum tab width is about 6,5 mm and the tab thickness minimum is 75 % from the thickness product

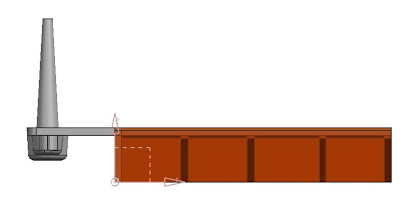

for more picture and drawing view,please look at picture below

(Top View of Tab Gate)

(Front view of Tab Gate)

(Side View of Tab Gate)

each picture is able to enlarge by clicking the picture.

2 comments:

Congratulation for the great post. Those who come to read your Information will find lots of helpful and informative tips. Injection Molded Parts

It is a very informative and useful post thanks it is good material to read this post increases my knowledge. Plastic Mold Components

Post a Comment