posts related to construction and part-bagianya slider has been my post, about the cooling on the slider, the basic construction for the slider, the slider and the main part, please see previous post to learn the basic construction and when we should use the slider, This post will discuss about when we need to use of the slider that use angular pin or just cam slider, what advantages and disadvantages of both types of construction such slider.

ANGULAR PIN

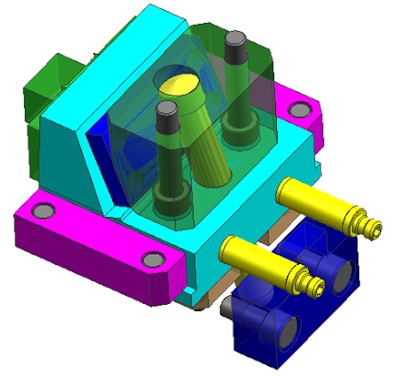

basically, the type of construction of the slider based on how to pull out the core slider is divided into three types, first use the angular pin,using the force of the angular pin at a certain angle, the slider block would be pull out, the second is a cam slider, just use the thrust of the spring and stopper on the slider, and calculating a stroke, cam slider allows you to easily pull the slider core, the third is the use of hydraulic or pneumatic system to pull the slider core, specifically for the third way is needed so that movements of individual controls in accordance when the slider open mold and mold close.picture below shows slider with angular pin system.

picture above shown standard complete construction for slider, it's include cooling plug, stopper (blue color), adjustment plate between locking block and slider core(blue), guide rel (pink) etc. angular pin system very common use in slider system, Angular sometimes do not have a round pin, shape the box is also commonly used, actually used the same angle, both will be used by considering the strength, structure, mold, and the available space.

The advantage is the use of angular pins can be used for parts that have undercut short or long, easy to maintain when the angular broken, just enough to change the angular pin. inexpensive in manufacture, and can be used for long-stroke slider to medium, the angular pin length has not touched bottom plate.

for instance,look at picture above if undercut wide for most of the parts, use the slider two pins with a diameter sufficient, then you will get a strong slider construction and safe.

CAM SLIDER

while the slider does not require angular cam pin, the cam slider there are several types of commonly used, the clamp type, two angle type, cam units type and one direction cam. because in using the cam to take calculation of a stroke is used, why?? it's to prevent slider core not be separated from the locking block, and the strength of the spring, so that true core slider can move and hit the stopper. cam slider can only be used for minor stroke (0.5 mm-5mm), small undercut, and not too wide undercut form.

a benefit is a cam slider can be used for high cycle time, mold construction, saving space, and easy assembly.

whereas the less than the limited form that can be undercut in the form, was difficult in the manufacture and maintenance.

Good News

Popular Posts

-

Various way available to calculate cooling time in injection mould, the easiest way of course using numerical method, software package like ...

-

this type of defect is caused by A molded product that is incomplete because the mold cavity was not filled completely. If a part short sh...

-

rapid heat temperature, is actually an old method that is often used to eliminate the weld line, the front cover products such as TV, is an ...

-

Many type of mold in the platic industry but generally mold devide in 3 big section there are : Two plate mold Two plate mold basically when...

-

A mold plate is any plate required to built a complete mold, in all plate use for molds have the main requirements, they are : 1. Good corro...

-

second previous post i have post about the slider parts and construction in complete mold base , then now i give a little brief when we need...

-

classification or types of mold injection very depend on what we need to make the plastic parts, because every parts have specific and uniqu...

-

it's difficult to list all company that provide any solution about injection machine, include manufacturer, injection molder, machine ma...

-

fan gate, is a gate spreading toward in to cavity, basically this gate is thin similarly with previous gate ( film gate ) and is used in sa...

-

Today, they are various plastic processing method available in industrial process, from the method of processing plastic we can divided into...

Labels

3plate

6 cavity

Assembly Inspection New Mold

Assembly Mold

basic construction

basic injection mold

blow mold

calculator

cavity cooling

Clamping force

collapsible core

collision gate

cooling construction

cooling time

core cavity

Diaphragm Gate

direct gate

disc gate

ejector system

fan gate

film gate

flat cooling

formula

gate

gate design

gate dimension

hot runner

Hot runner construction and method

How to inject Polystyrene

injection machine company

injection problems

injection process

Injection speed

insert

introduction

Jetting

leader pin

Locating Ring

loose core

melt line

moding preparation before injection proses

mol

Mold

mold calculator

mold classification

Mold Component

Mold Construction

mold cooling

mold defect

mold design

Mold Handling

Mold part and construction

mold plate

Mold Timing

Molding Defects

molding method

O ring

paralel and series cooling

pin ejector system

pin point gate

Plastic Processing Types

Polypropylene

Polystyrene

prepare the plastic material

Product Design

Rapid Cooling

return pin

Runner

runner balance

runner layout

runner system

safety

setting temperature and check condition of the molding

short shot

Shrinkage

side gate

sink mark

sleeve ejector

slider parts

Sprue

Sprue bush

step by step design

stripper ejector construction

support construction

support pin

tab gate

Terminology

top plate

undercut

venting system

video

Wall Thickness

warpage

weld line

Article TAG

Assembly Mold

Clamping force

Diaphragm Gate

Hot runner construction and method

How to inject Polystyrene

Injection speed

Locating Ring

Mold

Mold Component

Mold Construction

Mold Handling

Mold part and construction

Molding Defects

O ring

Plastic Processing Types

Product Design

Runner

Shrinkage

Sprue

Sprue bush

Terminology

Wall Thickness

basic construction

calculator

cavity cooling

collapsible core

cooling construction

core cavity

direct gate

disc gate

ejector system

fan gate

film gate

flat cooling

gate

gate dimension

hot runner

injection machine company

injection problems

injection process

leader pin

loose core

melt line

mold calculator

mold classification

mold cooling

mold design

mold plate

molding method

paralel and series cooling

pin ejector system

pin point gate

prepare the plastic material

return pin

runner balance

runner layout

runner system

setting temperature and check condition of the molding

side gate

sink mark

sleeve ejector

slider parts

step by step design

stripper ejector construction

support construction

support pin

tab gate

top plate

undercut

warpage

weld line

Injection Mold Lovers

Copyright © 2006 Injection Mold Design Tutorial, Technology and Engineering | Powered by Blogger