when the cavity space injected by plastic material, automatically empty space on the cavity will be filled with plastic material, the air in the cavity will be shifted to another place, what would happen if the air can not move, the air will experience a high pressure , so the temperature rises even higher, resulting in plastic that fills the cavity will be burning, the defect is called a burn, because of the importance of venting a lot of products that fail due to not properly inject the gas vent, especially for products that have a rib that thin and tall, as compared to thick products.

source : Plastic Today

The main function of the venting is

A. compressed air release

when compressed air is not expelled from the cavity, the plastic flow is inhibited, the result will be formed on a short shot of the product

2. compressed air will produce a gas with high temperature and burn the plastic around it, resulting in a defect burn marks, the product looks like a burn, this will greatly affect the look of the product.

3. when the gas mixed with plastic, the plastic will generate an uneven structure, which will reduce the strength of the product / mold parts produced, stress concentration also common in this region, which occurs due to the plastic notch.

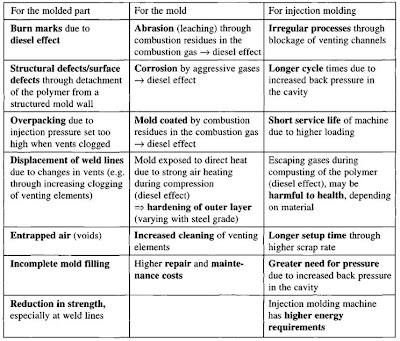

for more detail about effect of adequate of venting on injection mold, please see on picture below

part of venting, can divide on 2 section, land and groove, land is always contact with plastic melt, it's deep about 0.01 mm until 0.02 mm, depend on viscosity of material, relief of vent or gas land is about 1 mm until 2mm, but you must remember for rubber all the number above can't applied, gas vent on rubber material is very special, because rubber has low viscosity.

when designing the gas vent / venting on injection mould, make sure that all of the groove must have exhaust groove that connect to atsmosfer.