venting is a small part of the mold design, on the design process also requires a very short time, perhaps only 10% or less of the total time required in designing.sometimes is frequently neglected until molding trials indicate mold inadequacies related to venting. if we understand the purpose and function of vents, it's can assists mold designer to design where clearly additional vents required.

when the cavity space injected by plastic material, automatically empty space on the cavity will be filled with plastic material, the air in the cavity will be shifted to another place, what would happen if the air can not move, the air will experience a high pressure , so the temperature rises even higher, resulting in plastic that fills the cavity will be burning, the defect is called a burn, because of the importance of venting a lot of products that fail due to not properly inject the gas vent, especially for products that have a rib that thin and tall, as compared to thick products.

source : Plastic Today

The main function of the venting is

A. compressed air release

when compressed air is not expelled from the cavity, the plastic flow is inhibited, the result will be formed on a short shot of the product

2. compressed air will produce a gas with high temperature and burn the plastic around it, resulting in a defect burn marks, the product looks like a burn, this will greatly affect the look of the product.

3. when the gas mixed with plastic, the plastic will generate an uneven structure, which will reduce the strength of the product / mold parts produced, stress concentration also common in this region, which occurs due to the plastic notch.

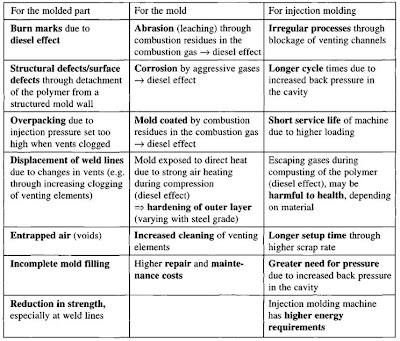

for more detail about effect of adequate of venting on injection mold, please see on picture below

part of venting, can divide on 2 section, land and groove, land is always contact with plastic melt, it's deep about 0.01 mm until 0.02 mm, depend on viscosity of material, relief of vent or gas land is about 1 mm until 2mm, but you must remember for rubber all the number above can't applied, gas vent on rubber material is very special, because rubber has low viscosity.

when designing the gas vent / venting on injection mould, make sure that all of the groove must have exhaust groove that connect to atsmosfer.

Good News

Popular Posts

-

Various way available to calculate cooling time in injection mould, the easiest way of course using numerical method, software package like ...

-

rapid heat temperature, is actually an old method that is often used to eliminate the weld line, the front cover products such as TV, is an ...

-

this type of defect is caused by A molded product that is incomplete because the mold cavity was not filled completely. If a part short sh...

-

Many type of mold in the platic industry but generally mold devide in 3 big section there are : Two plate mold Two plate mold basically when...

-

A mold plate is any plate required to built a complete mold, in all plate use for molds have the main requirements, they are : 1. Good corro...

-

second previous post i have post about the slider parts and construction in complete mold base , then now i give a little brief when we need...

-

classification or types of mold injection very depend on what we need to make the plastic parts, because every parts have specific and uniqu...

-

it's difficult to list all company that provide any solution about injection machine, include manufacturer, injection molder, machine ma...

-

fan gate, is a gate spreading toward in to cavity, basically this gate is thin similarly with previous gate ( film gate ) and is used in sa...

-

Today, they are various plastic processing method available in industrial process, from the method of processing plastic we can divided into...

Labels

3plate

6 cavity

Assembly Inspection New Mold

Assembly Mold

basic construction

basic injection mold

blow mold

calculator

cavity cooling

Clamping force

collapsible core

collision gate

cooling construction

cooling time

core cavity

Diaphragm Gate

direct gate

disc gate

ejector system

fan gate

film gate

flat cooling

formula

gate

gate design

gate dimension

hot runner

Hot runner construction and method

How to inject Polystyrene

injection machine company

injection problems

injection process

Injection speed

insert

introduction

Jetting

leader pin

Locating Ring

loose core

melt line

moding preparation before injection proses

mol

Mold

mold calculator

mold classification

Mold Component

Mold Construction

mold cooling

mold defect

mold design

Mold Handling

Mold part and construction

mold plate

Mold Timing

Molding Defects

molding method

O ring

paralel and series cooling

pin ejector system

pin point gate

Plastic Processing Types

Polypropylene

Polystyrene

prepare the plastic material

Product Design

Rapid Cooling

return pin

Runner

runner balance

runner layout

runner system

safety

setting temperature and check condition of the molding

short shot

Shrinkage

side gate

sink mark

sleeve ejector

slider parts

Sprue

Sprue bush

step by step design

stripper ejector construction

support construction

support pin

tab gate

Terminology

top plate

undercut

venting system

video

Wall Thickness

warpage

weld line

Article TAG

Assembly Mold

Clamping force

Diaphragm Gate

Hot runner construction and method

How to inject Polystyrene

Injection speed

Locating Ring

Mold

Mold Component

Mold Construction

Mold Handling

Mold part and construction

Molding Defects

O ring

Plastic Processing Types

Product Design

Runner

Shrinkage

Sprue

Sprue bush

Terminology

Wall Thickness

basic construction

calculator

cavity cooling

collapsible core

cooling construction

core cavity

direct gate

disc gate

ejector system

fan gate

film gate

flat cooling

gate

gate dimension

hot runner

injection machine company

injection problems

injection process

leader pin

loose core

melt line

mold calculator

mold classification

mold cooling

mold design

mold plate

molding method

paralel and series cooling

pin ejector system

pin point gate

prepare the plastic material

return pin

runner balance

runner layout

runner system

setting temperature and check condition of the molding

side gate

sink mark

sleeve ejector

slider parts

step by step design

stripper ejector construction

support construction

support pin

tab gate

top plate

undercut

warpage

weld line

Injection Mold Lovers

Copyright © 2006 Injection Mold Design Tutorial, Technology and Engineering | Powered by Blogger

9 comments:

Hello,

could you please contact me if you are interested in outsourcing of mold constructions.

My company is plastic processing company, we have our own moldshop but we need to outsource mold constructions.

If interested, mail me at info @ bema . ba

Best regards

Nedim Sabic

hi Mr. Nedim, i was send email to yours, i'm glod receiving your offer. please reply my email

In modern plumbing, a drain-waste-vent (or DWV) is part of a system that removes sewage and greywater from a building and regulates air pressure in the waste-system pipes, facilitating flow. Waste is produced at fixtures such as toilets, sinks and showers, and exits the fixtures through a trap, a dipped section of pipe that always contains water. All fixtures must contain traps to prevent sewer gases from leaking into the house. Through traps, all fixtures are connected to waste lines, which in turn take the waste to a soil stack, or soil vent pipe. At the building drain system's lowest point, the drain-waste vent is attached, and rises (usually inside a wall) to and out of the roof. Waste is removed from the building through the building drain and taken to a sewage line, which leads to a septic system or a public sewer. Cesspits are generally prohibited in developed areas. Restaurant Software

JINHUA specializes in producing all kinds of plastic blowing mould and injection mould as barrel mould,plastic mannequin mould

,cap mould auto parts ect for more than 20 years, an annual production of more than 900 sets of various types of plastic duct mould

.

I have found so many information about injection mould venting system in this posting.It will more helpful to Mould Maker to design their injection mould vents required.

so easy to understand for us who know not so much about [url=“http://www.jmtmould.com/”]plastic injection mould[/url]design. Thanks for sharing

That is really good and informative post, it contains good and healthy information about moud venting system. Thank you for sharing it and keep posting more such posts

I am glad to read your blog. your blog is really cool and great. your blog is really awesome and cool.your blog is really great.thanks for sharing the nice and cool post. In this site piknu we can see nay things on instagram, please visit it

Post a Comment